Ho Ho Ho! Tis the season to be jolly, fa la la… la… la la la!! Sorry folks, I’m not much of a singer, but I can play jingle bells on the Jake brake after about three glasses of egg nog. Then I just fall asleep and dream of all the things I would like Santa to bring me when he slides down the chimney. Chrome, stainless, and all things shiny for my parking lot princess… what did you think I would be dreaming of, chestnuts roasting by the fire or sugar plums dancing in my head? Nope, can’t do that, I’m on a sugar-free diet, watching my waistline so I don’t get mugged at Walmart in the cookie isle or be mistakenly kidnapped for ransom and held as the Big Guy. Don’t laugh, it could happen this time of year.

This is the season of giving, so if you’re not sure anyone is going to gift you “truck parts” then be sure to get some for your partner – the truck. It’s not the same as getting it for yourself since technically it’s for your partner, the other half of a well-oiled machine, and I’m sure you talk to it like it’s a person every day. Many of our readers call their trucks by name. On Dasher, on Comet, on Blitzen and you, too, Razerfer. Wake the heck up, we got work to do – what do you think this is, summer camp?! There’s freight to be hauled and all of them little boys and girls are depending on us to rocket through the night.

It’s time to kick the tires and light some fires! “The pre-trip is almost done, just a few more things to mark off… headlamps (check)… chicken lights (check)… starlights (check)… taillights are all you can see as we light up the Christmas sky. We gone, bye, bye!” But wait – there’s more, that’s not the end of this story. I went back and looked over a few of my December articles to see what I might have said so I don’t repeat myself. Mostly I wrote stories about holidays and family gatherings. We all start celebrating in November for Thanksgiving, and most will stay in the festive mood till a couple weeks after New Year’s Eve. As I recall, that’s about the time the credit card bills start to roll in… ouch! That is unless you are a truck driver – we don’t get to do too much celebrating, because that tends to be our busiest time of the year.

Between increased freight levels for gift giving and year-end inventories, we are all on the move. This is one time when it doesn’t make any difference what line of transportation you’re in, it’s hectic. Local drivers are just as important as the long haul guys or gals who push the import products from dock to shore and the freight lines who move it across the inland infrastructure. It’s not just dry goods, either – there’s food products, fresh produce, and frozen foods. Can you say cranberry sauce or giblet gravy? Then, for year-end inventory, many of the last minute purchases are approved for construction projects, or replacement purchases to carry over into next year’s continuous and seamless distribution and/or supply chain. I get worn out just thinking about it. Just a little early gift from our faithful 10-4 family to all of you. As a special gift to DTM (Dan The Man), our editor and chief, I will try to write fewer words and use more pictures to demonstrate the process.

I chose the title for this article “Anatomy of a Gift” purposely to help showcase some of the work necessary to manufacture and produce high-end, top quality truck parts. These are products that can and will hold up to the rigors of road life. I’ve been a lifelong consumer of better built products. Not as a brand name, but as a category of replacement parts for our equipment. First, let me be clear, never dress up your company ride at your personal expense! This can be a pitfall for company drivers if they are forced to separate from the employment and then are required to leave all that “investment” on the truck for the next driver. Read your employment contract carefully beforehand and be sure you can remove personal items from your carrier-owned vehicles upon separation. It’s also a good idea to get your carrier to sign off on any changes or “self-imposed improvements” you may want to make, as you don’t want to be the first driver fired for altering company equipment. We have that provision in our driver policy, because I have a certain look, and don’t want it altered.

In today’s marketplace, many of the carriers out there have a written policy that limits or restricts any changes to company equipment. However, there are also many companies who value their long term, professional, representative drivers – those who go the extra mile in caring for and preserving a positive image of the company and its valued customers. I can name a few who not only appreciate those drivers, but they also reward them with extra gifts of shiny stuff and a standout truck. If you are one of those few, then this article is for you, too. Now, let’s get into the meat and potatoes (or the turkey and dressing) of this month’s information.

I want to be abundantly clear, as I have written many times about one certain fabrication shop, Pickett Custom Trucks (PCT) in Buckeye, Arizona. I also do a little work there for the owner and management team, Mr. Rod Pickett and his sidekick, the fabrication guru, Steve Gringo (AKA Steve Mitchell). Their shop is only one of many who do wonderful custom work. They also carry a line of products deemed worthy of their reputation. Made to order parts that are not only beautiful to hold, but they fit your application perfectly.

We have all seen the chrome shop displays with “replacement parts” for (insert your brand and type of equipment here). It’s priced at whatever the market will stand, or drivers are willing to pay. Most do not carry any warranty or have any return policy. This is important when you are laying out a fair price for what you believe to be quality work or workmanship. Note: most dress up or cover up parts are listed as warranties by manufacturers, not distribution outlets (chrome shops). In short, that means if it bends, bend it back, if it rusts, that’s driver neglect, and if it breaks, don’t call us, call 1-800-BAD-PART, then send it to the scrap pile!

If you’re wondering, “How do I get a true made-to-order part that fits my application?” What is the process of purchasing a special part and how much should it cost? First, let’s address the issue of cost. All prices are subject to the complexity of the product. For example, a standard I-panel (the filler panel below the frame and between the fuel tanks) for a Peterbilt 389 with standard spacing of 135-gallon tanks is a product that is easily replicated and duplicated once there is a pattern, so that’s somewhat of a more common request. Now, keep in mind, the more you option that standard part by adding lights or recessed pockets with hidden features or whatever, the more complicated it becomes. The type of lights you choose can make a huge difference in pricing, too. I’m reminded of an old phrase: “The cost of cool ain’t cheap, and cheap ain’t cool!”

If you are requesting a one-off part for your 2007 Volvo, that’s a little different, since most fabrication shops don’t have a pattern worked up to work with. That means someone has to either find a truck just like yours to measure or you will need to make an appointment to have your specific truck measured to ensure the placement is correct and that they are comfortable taking on your request. I recommend the later choice so there is less chance of making mistakes. That doesn’t mean it can’t be done, it means it’s not a cookie-cutter piece, and the price will reflect that. Also, don’t be alarmed if you are asked to place a downpayment on your work order – it’s common practice to put a little skin in the game before they begin to process your request. None of us want to put forth a great effort building something “special” only to get cheated when no one shows up to claim it.

In today’s metals market, a single sheet of aluminum can run $200-$500, and good quality 304 stainless can be between $250 and $1,200. Most I-panels require about a half sheet of material, depending on the design or style. For reference, I inquired with our fabrication guru on the mill, grade, or thickness of preferred materials. His recommendation was dependent on the application. His range was between 16 gauge and 1/8 inch. Many of the pre-packaged parts are made using 20 gauge material, which is thinner by design and cheaper to mass produce. Depending on the process of manufacturing, this can also affect the structure of the bends and therefore be more prone to cracks and breaks. To the average consumer, that may result in disappointments and/or failures. With all this in mind, just the cost of materials, not to mention highly skilled labor, is the difference between “custom” and “cuss-um” truck parts!

Okay, with materials out of the way, let’s talk process and labor. Like any other true tradesman, they are worth their weight in gold. And I’m not just speaking of the fabrication guy, but the paint and body guys, as well. Note to all the young people out there who aren’t sure how or where to find a career path – many of these jobs pay well and some have a promising future. If you might be wondering why I feel qualified to speak on this subject it’s because I have been the test dummy for many of the products on the market today. Not with the current manufacturers, but with some of the original designers of these products. I feel like the guy from State Farm Insurance (I know a thing or two because I’ve seen a thing or two).

Some pertinent advice to those who are currently in the process of or plan to in the future build a truck worthy of the pages in 10-4 Magazine – there are no short cuts to success. A knock off part may cosmetically look the same, but it will not last or perform like a true custom truck part. My confidence comes from hands-on experience with broken parts and redesigned ones that eventually get replicated by the name-brand distribution companies that flood the market with look-a-like cookie-cutter items. It’s still buyer beware – if you want quality, then take the time to search it out. Personally, I’m still running my original I-panel built by and “gifted” to me by Steve Gringo (my son) more than 10 years ago. It doesn’t get pulled off at the end of a show season or the beginning of winter either. It is a true testament to the skill of a craftsman, the attention to materials, and the lasting endurance of a well-made product. Nice job, son!

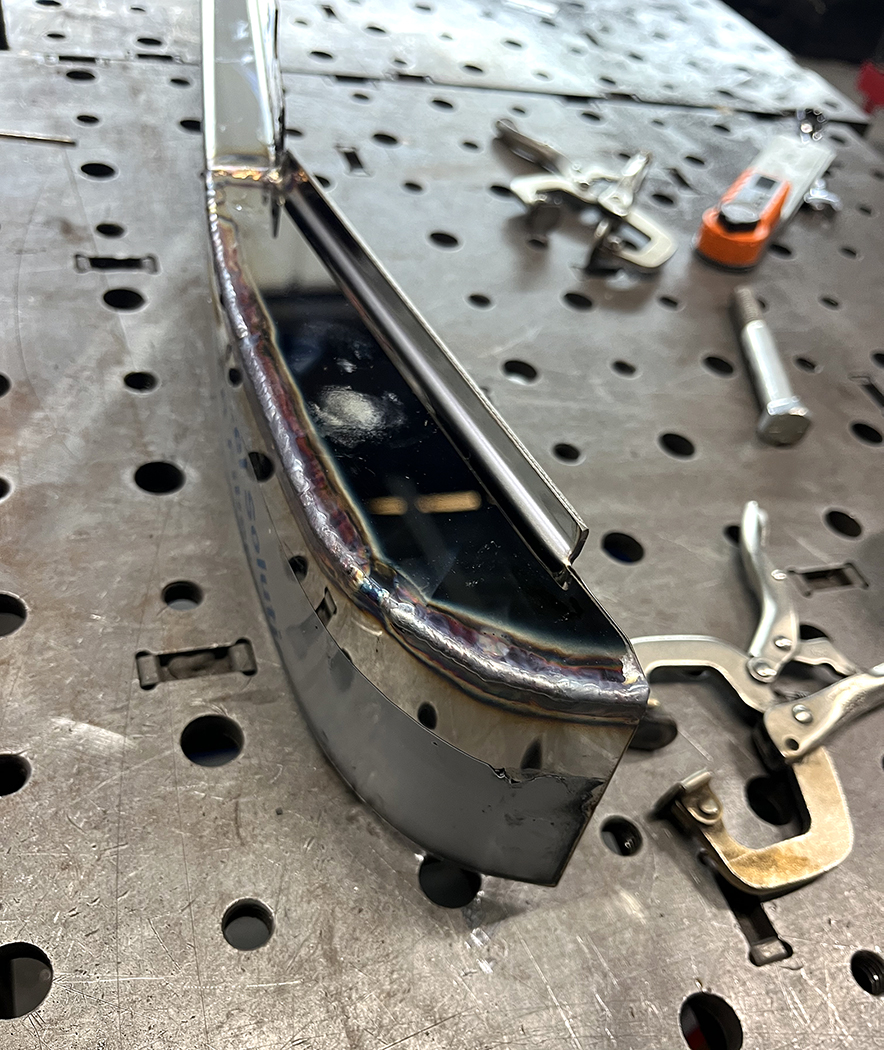

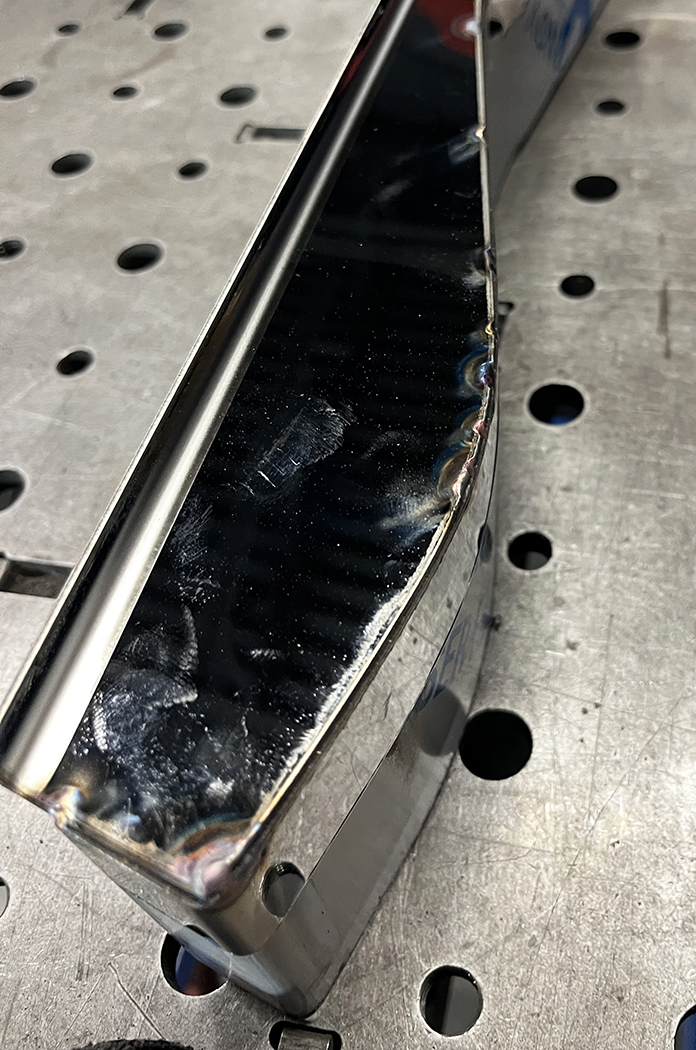

Next, let me address the process of cutting and/or shaping the raw materials into a work of art worthy of gifting to yourself or someone else. The machines necessary to do all these things are big, bold, and beautiful – and very expensive. They also require people trained to use them. This isn’t a task you learn in a weekend while playing basketball. Many of these products are made by one craftsman, using multiple technologies, theories, and applications of expertise. From the initial drafting process to the conversion of long hand measurements, to machine language, to digital control of the plasma table, the program then goes to the heavy break for exact and sharp bends, to the final process of hand welding or tig welding the shape for strength and durability.

The sign of a better built product is one that does not show a start or stop of the process. To achieve this, all welds are hand ground to perfection and sanded before polishing or paint is applied. In most cases, the welding process is used to add body to the seam and not stretch the existing materials, unlike the stamping process, which can weaken the seam and lead to premature failure. This process will generally give a part a more uniform appearance, and the final inspection should be the reflection of craftsmanship, not crap-an-ship!

Lastly, let me touch on the time requirements for products of this caliber. Any production company can stamp or cut products from a continuous roll of steel, aluminum or stainless, then slip that blank into a high strength hydraulic press using a product die to form the desired shape. Wham bam, thank you, mam! Then, stack it on a pallet and ship it out the door. That doesn’t make it good, it makes it cheap and ready-made, meaning it (or you) will look just like everyone else. The parts I am talking about are for the driver/owner who really wants to stand out among his or her peers. Budget for a few big ticket items that make a statement, then select a style of products you prefer. Remember, most custom shops specialize in specific types of product lines. Contact a shop you trust and make an appointment to discuss having pieces made to order. Their time and experience are valuable, and not a commodity to be wasted.

Choosing the right shop or builder is a crucial step in the process since the parts they build can be a considerable investment and you probably plan to keep them for a long service life. This will also allow you to plan your timeframe around their production schedules and give the fabrication shop ample time to prep materials – it is not a simple task to plan, design, mock-up, test fit, and then finally build or produce a custom part. It will also give you a clear explanation of their process and price structure. And, any time a product builder is personally involved, they can discuss and express the pros or cons of specific designs. Also, having a well-informed customer can help the process go better, as well. Keep all this in mind when considering having custom parts (gifts) made.

Merry Christmas to everyone from Aunt Barb, Penny the pooch, and myself. We wish you all Seasons Greetings from the North Country up here in Michigan. If you have asked for some cool parts for your truck as gifts, let’s hope the giver has read this article and now better understands the anatomy (and process) of these types of gifts. As we reflect on this past year, we make a toast with a mug of hot spiced chocolate as we snuggle in front of the fireplace and watch it snow, wishing you all a Happy New Year, too! Here’s hoping 2026 will be our best year yet, 10-4!